In the world of industrial roller brush types, two of the most widely used solutions are wire brush rollers and nylon brush rollers. Each has unique strengths, applications, and limitations. When it comes to making the right investment for your production line, understanding the differences can help you maximize efficiency, extend equipment life, and reduce operating costs.

1. Wire Brush Rollers: Strength in Aggressive Cleaning

Wire brush rollers are made with steel, stainless steel, or brass wires. They are well-suited for heavy-duty industrial applications where durability and cutting power are required.

Key Advantages:

Limitations:

2. Nylon Brush Rollers: Versatility and Gentle Finishing

Nylon brush rollers are made from synthetic fibers such as nylon 6, nylon 66, or abrasive nylon with silicon carbide or aluminum oxide. They are ideal for applications requiring flexibility and precision without damaging the material.

Key Advantages:

Limitations:

3. Roller Brush Comparison Table

| Feature / Property | Wire Brush Roller | Nylon Brush Roller |

|---|---|---|

| Durability | Very High (heavy-duty use) | Medium (light to medium-duty use) |

| Surface Impact | Aggressive, can scratch soft materials | Gentle, safe for delicate surfaces |

| Best For | Rust removal, deburring, metal surface prep | Food processing, electronics, light cleaning |

| Temperature Resistance | High (up to 600°C depending on wire material) | Low to Medium (usually below 120°C) |

| Cost | Higher initial investment | More cost-effective upfront |

| Maintenance | Occasional wire replacement needed | Requires more frequent replacement |

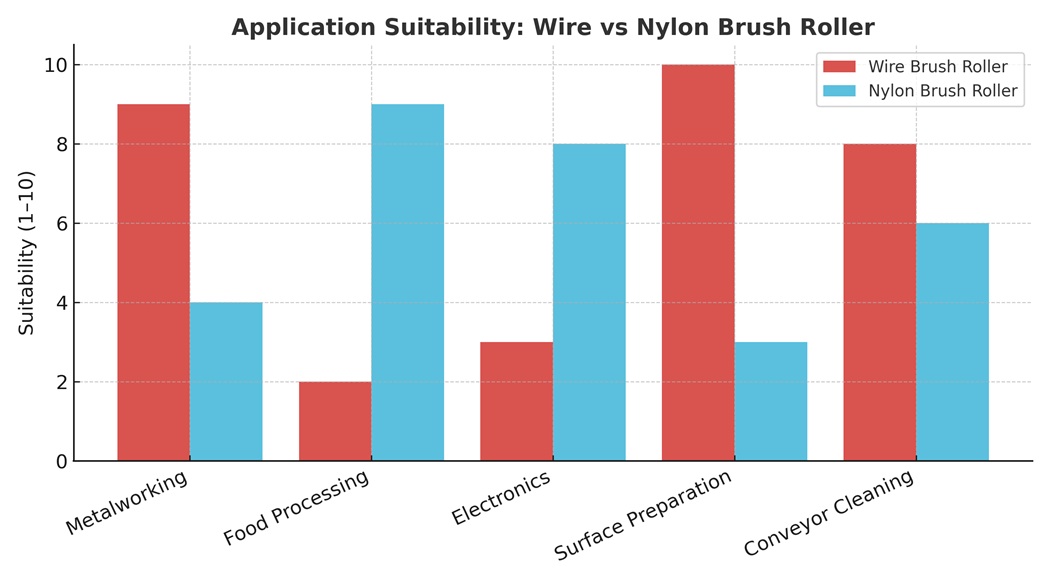

4. Industry Applications: Wire vs Nylon Brush Roller

To visualize the application areas of these industrial roller brush types, here’s a simple breakdown:

Wire Brush Roller Applications:

Nylon Brush Roller Applications:

Copyright © 2026 Anqing Hongyue Machinery Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported