A perforation needle roller makes small, exact holes in soft materials like plastic films or packaging. You use this tool when you want neat, even tiny holes for air or water to pass through. Knowing how this tool works helps you pick the best one for your job and get better results in your work.

Perforation Needle Roller Basics

What It Is

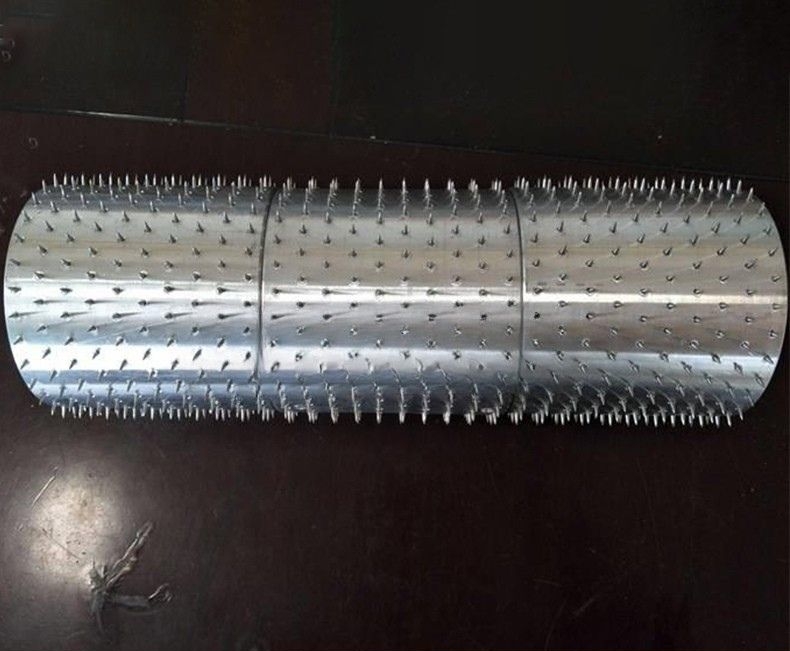

A Perforation Needle Roller is a special tool. It helps you make tiny, exact holes in soft materials. Many factories use this tool for plastic films and packaging. Some even use it for medical supplies. The roller looks like a cylinder with many small needles on it. These needles are very sharp and spaced out evenly. When you use the roller, it pushes against another roller. This second roller holds the material steady. The needles poke through the material and make clean holes.

Most Perforation Needle Rollers are made from high carbon steel. This makes them strong and long-lasting. The needles are ground to be extra sharp and smooth. This helps make neat holes with no rough edges. If you need to make holes quickly or want better packaging, this roller is a good tool.

How It Works

To use a Perforation Needle Roller, put your material between the two rollers. As the rollers spin, the needles press into the material. They make small holes as they turn. The holes are all the same size and spaced evenly. This way, the holes have smooth edges and look neat.

This tool is great for big jobs. It works fast and does not need much effort. If you want your products to let air or water pass through, this tool helps. Many companies use it for food packaging and medical wraps. It is also used for making films that can breathe.

Sometimes, you might have problems with the roller. You could see holes that are not even or marks on the material. You can fix these by cleaning the rollers often. Check for parts that are worn out. Adjust the pressure if you need to. The table below lists some common problems and how to fix them:

|

Challenge |

Solution |

|---|---|

|

Uneven perforation and inconsistent line length |

Clean and check rollers and belts often. Replace worn or broken parts. Adjust roller pressure. Use sensors to monitor feed rate. Test new materials before large jobs. |

|

Marks or dents left by rollers |

Regularly inspect and maintain rollers and belts to ensure they are clean and in good condition. |

|

Misalignment of holes |

Check and adjust pressure and tension settings frequently to ensure proper alignment. |

|

Quality control issues |

Implement real-time monitoring using sensors and cameras to detect problems quickly. |

Doing regular checks and setting up the tool right helps you get the best results. If you want to make your production line better, this tool is a smart choice. Many people want rollers with special needle patterns. This makes the tool useful for many different jobs.

Types of Perforation Needle Rollers

You can pick cold or hot rollers for making holes. Each kind uses a different way to make holes in materials. Cold Needle rollers have mechanical needles that punch holes. Hot rollers use heated needles to melt and seal the hole edges. The table below shows how they are different:

|

Type |

Technology Used |

Ideal For |

|---|---|---|

|

Cold Microperforation |

Mechanical needles |

High-speed production, thin materials |

|

Hot Microperforation |

Heated needles |

Heat-sealable films, sealed holes |

Cold rollers are good for fast jobs and thin materials. Hot rollers seal the hole edges, which helps keep things fresh in packages.

Manual and Automatic Rollers

There are manual and automatic Perforation Needle Rollers. Manual rollers let you control the work by hand. These are best for small jobs or testing new materials. Automatic rollers use machines to move the rollers and material. These are better for big jobs. You get faster and more even holes with automatic rollers. If you want to make packaging better or need to do lots of work, automatic rollers are a good choice.

Tip: Use a manual roller for small jobs or testing. Use an automatic roller for big jobs and steady results.

Custom Needle Patterns

You can get rollers with special needle sizes and patterns. This helps you match the tool to your material and project. The right needle size and pattern can make your holes look better. Here are some things to remember:

Pick the smallest needle that fits your thread or material to stop damage.

Try different needle and thread types on scrap before your main job.

Change dull needles often so holes stay neat and materials do not get hurt.

Big needles can make holes too large and damage soft materials.

Small needles can cause friction and make threads fray.

Sharp points are best for heavy materials, and ballpoint needles work well for soft or knit materials.

Custom patterns let you make cool effects, like 3D holes or special airflow designs. You can make your product look and work better by picking the right pattern.

Materials and Applications Compatible Materials

A Perforation Needle Roller works on many soft materials. You can use it on plastic films, wraps, paper, and textiles. These materials bend and stretch without ripping. Some people use this tool for medical wraps or food packaging that needs to breathe. If you want cool 3D hole designs, you can pick rollers with special needle patterns. These patterns help products look different and let air move better.

How thick and bendy the material is matters a lot. Thick materials need stronger needles and more force. Soft materials need careful control of hole size and spacing. If you do not check these things, you might hurt the material or make it weak. Picking the right roller and settings gives you neat holes and keeps your product strong.

Tip: Test your material with the roller before big jobs. This helps you avoid problems and get good results.

Industry Uses

Many businesses use microperforation to make products work better. Plastic, textile, paper, and food companies use this tool a lot. The table below shows how much these industries use Perforation Needle Rollers:

|

Industry |

Usage Rate |

|---|---|

|

Plastic Industry |

High |

|

Textile Industry |

High |

|

Paper Industry |

Moderate to High |

|

Food Industry |

Moderate to High |

Microperforation helps packaging and food in many ways:

Fresh food and baked goods last longer

Packages breathe better and control water drops

Easy tear lines make opening simple

Using this tool is good for the planet too. Perforation Needle Rollers help make packaging greener by using less material and making recycling easier. The table below shows how this helps:

|

Contribution |

Description |

|---|---|

|

Reducing Material Usage |

Lets you use thinner materials and less plastic or paper. |

|

Improving Recyclability |

Makes recycling easier by using just one kind of plastic. |

|

Minimizing Food Waste |

Keeps food fresh longer and stops waste. |

If you want packages that breathe, last longer, or open easily, try a Perforation Needle Roller. This tool helps you meet new packaging needs and supports green manufacturing.

Benefits and Features Efficiency and Precision

You want your factory to work quickly and easily. A Perforation Needle Roller helps you make lots of products fast. The roller makes neat holes very quickly. You get the same good results every time. This means you waste less and make fewer mistakes. This tool is great for packaging that needs tiny holes for air or water. You can use it for food packages, medical wraps, and films that need to breathe.

When you use this roller, you see better quality. The sharp needles go through materials without making rough edges. The holes look neat and help your product work well. If you want to make more products or keep high quality, this tool helps you do that.

Tip: Pick a roller with high-carbon needles for better results and longer use. This keeps your work fast and your products looking good.

Customization and Durability

You can change the roller to fit your needs. You can pick needle patterns and sizes for your project. You might need special holes for food packages or medical supplies. Customizing the roller makes your work easier and better.

Taking care of the roller is easy. You can change pinned parts instead of the whole roller. This saves you money and time. Clean and check the roller often to keep it working well. High-carbon steel makes the roller last a long time.

Here is a table that shows how customizing helps the roller work better and last longer:

|

Feature |

Benefit |

|---|---|

|

Tailored Designs |

Fits your needs, works better and lasts longer |

|

Pinned Segments |

Easy to change, saves money |

|

High-Carbon Needles |

Makes neat holes and lasts a long time |

|

Versatile Applications |

Works with many materials, great for fast packaging and making things |

If you want a tool that fits your work and lasts, pick a roller with custom parts. You get better results and spend less on new rollers. This makes your work easier and saves money.

Now you understand how a perforation needle roller works. This tool makes neat holes in your materials. You can pick different punch sizes for each job. It uses advanced technology and works in many industries.

|

Advantage |

Description |

|---|---|

|

High-Precision Perforation |

Makes lots of holes close together with almost no mistakes (≤0.001 mm). |

|

Customizable Punch Sizes |

Lets you pick hole sizes from 0.03 mm to 20 mm for different materials. |

|

Advanced Technology |

Uses the newest technology, like temperature control. |

When you choose a needle roller for packaging or other jobs, look at these things:

|

Factor |

Description |

|---|---|

|

Material |

The material you pick changes how strong and long-lasting it is. |

|

Size and Diameter |

The right size stops mistakes and keeps work moving. |

|

Pin Population and Density |

How the pins are set up changes how good the holes are. |

Think about what your material needs before you decide. The right roller gives you better results and helps your business.

Copyright © 2026 Anqing Hongyue Machinery Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported