In modern production lines, small improvements in conveyor performance compound into major gains in throughput, product quality, and cost savings. One often-overlooked component that delivers outsized benefits is the industrial needle roller — a form of conveyor roller brush designed to clean, align, or finish items as they move through the system. When specified and installed correctly, needle rollers significantly enhance line efficiency, reduce downtime, and lower total operating cost.

Conveyor systems move material reliably — but contaminants, stray debris, product buildup, and static cling create friction, jams, and rejects. Needle rollers (cylindrical rollers densely populated with needle-like bristles) perform continuous cleaning, de-dusting, and gentle surface treatment inline, so:

This translates into measurable improvements in cycle time and first-pass yield.

Primary efficiency gains

1. Reduced jams and stoppages

By sweeping debris away from belt surfaces and product edges, needle rollers minimize the frequency of conveyor blockages. Fewer stoppages mean more continuous run-time and higher hourly throughput.

2. Improved sensor reliability & fewer false rejects

Photoeyes, barcode scanners, and vision systems are sensitive to dust and residue. A well-placed conveyor roller brush ahead of the sensing zone keeps optics clean — lowering false readings and reducing downstream manual inspections.

3. Better product presentation & reduced rework

For packaging lines and quality-inspection points, uniform surface cleanliness ensures labels adhere correctly and visual inspection systems can operate without interference. That reduces rework and scrap.

4. Lower maintenance labor and material costs

Needle rollers are passive (low-power) devices that reduce the need for frequent manual cleaning. Less cleaning means lower labor cost and less use of solvents or replacement wipes — a direct operating cost saving.

When an industrial brush roller manufacturer designs a roller for your line, they consider:

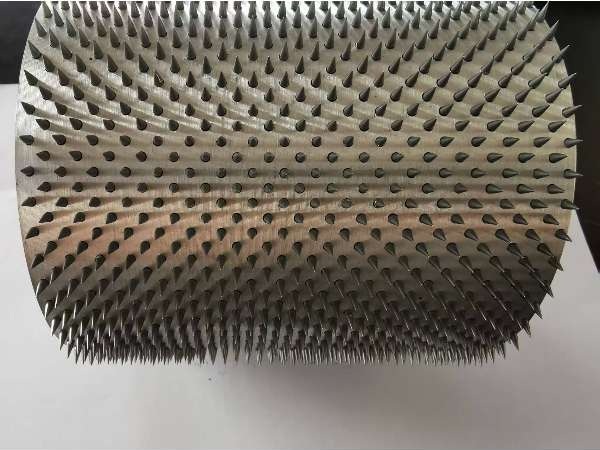

Bristle material — nylon, steel, stainless, or specialty filaments for high-temp or chemical environments.

Bristle density & stiffness — denser, stiffer bristles for heavy-duty scraping; softer filaments for delicate surfaces.

Roller diameter & length — sized to match product width and contact area.

Mounting & drive options — free-spinning vs motor-driven, fixed vs spring-loaded mounting for pressure control.

Modularity & changeover — quick-swap cartridges for rapid maintenance and format changes.

Ask your supplier for performance data (bristle life, recommended RPM, expected cleaning volume per hour) — reputable industrial brush roller manufacturers will provide this.

Application

Food & beverage lines: removing crumbs, sealing residue, or product fibers prior to labeling.

Printing & converting: cleaning web edges and eliminating fine dust before lamination.

Textile & nonwoven: removing loose fibers to prevent defects downstream.

Metalworking: deburring or surface conditioning before finishing stages (with metal filament rollers).

Electronics assembly: anti-static filament options to clear particulates without damage.

Industrial needle rollers are a high-impact, relatively low-cost upgrade for conveyor systems that struggle with debris, misfeeds, or sensor errors. Working with an experienced industrial brush roller manufacturer to choose the correct conveyor roller brush configuration is the key to unlocking sustained improvements in industrial needle roller efficiency.

Copyright © 2026 Anqing Hongyue Machinery Equipment Co., Ltd. All Rights Reserved.

Network Supported

Network Supported